Highest safety – for fellow road users as well

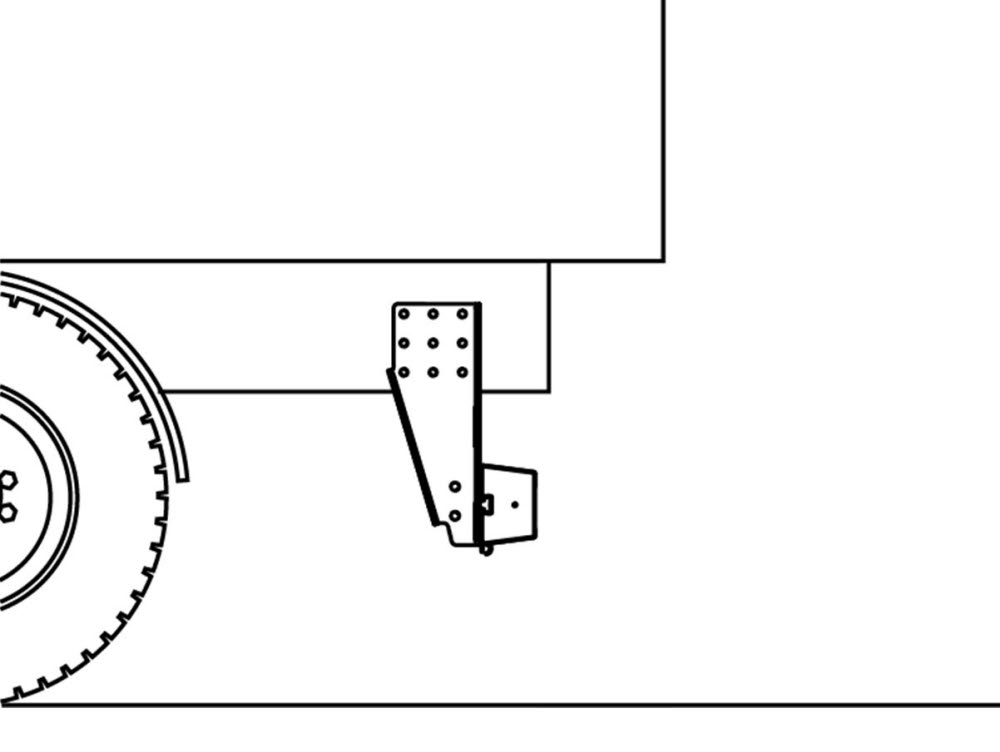

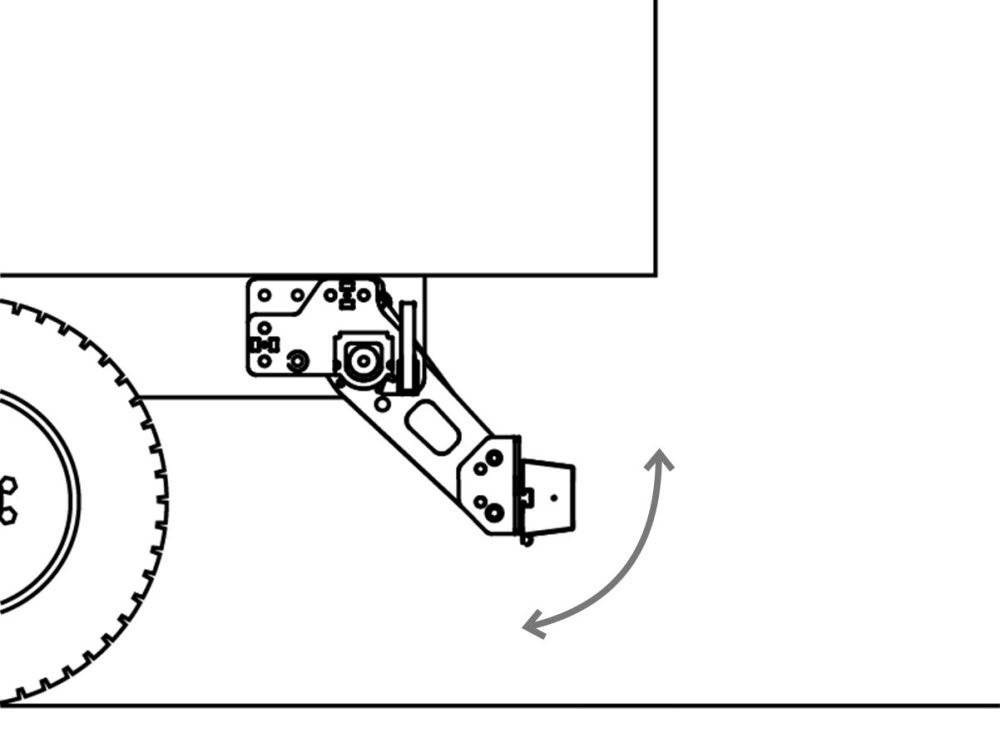

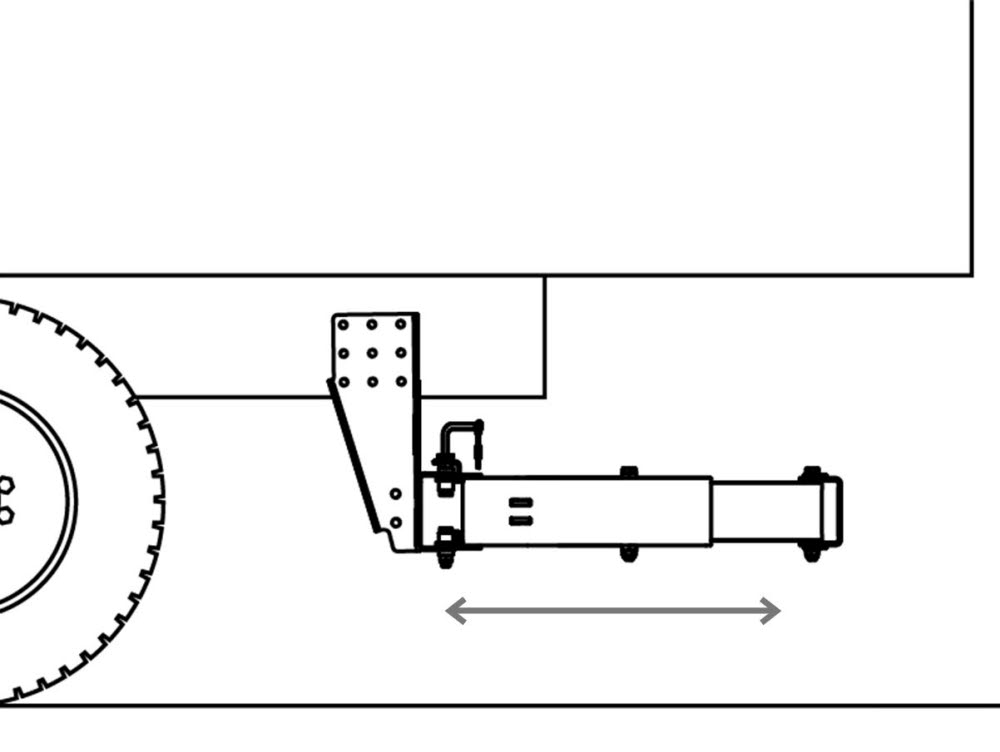

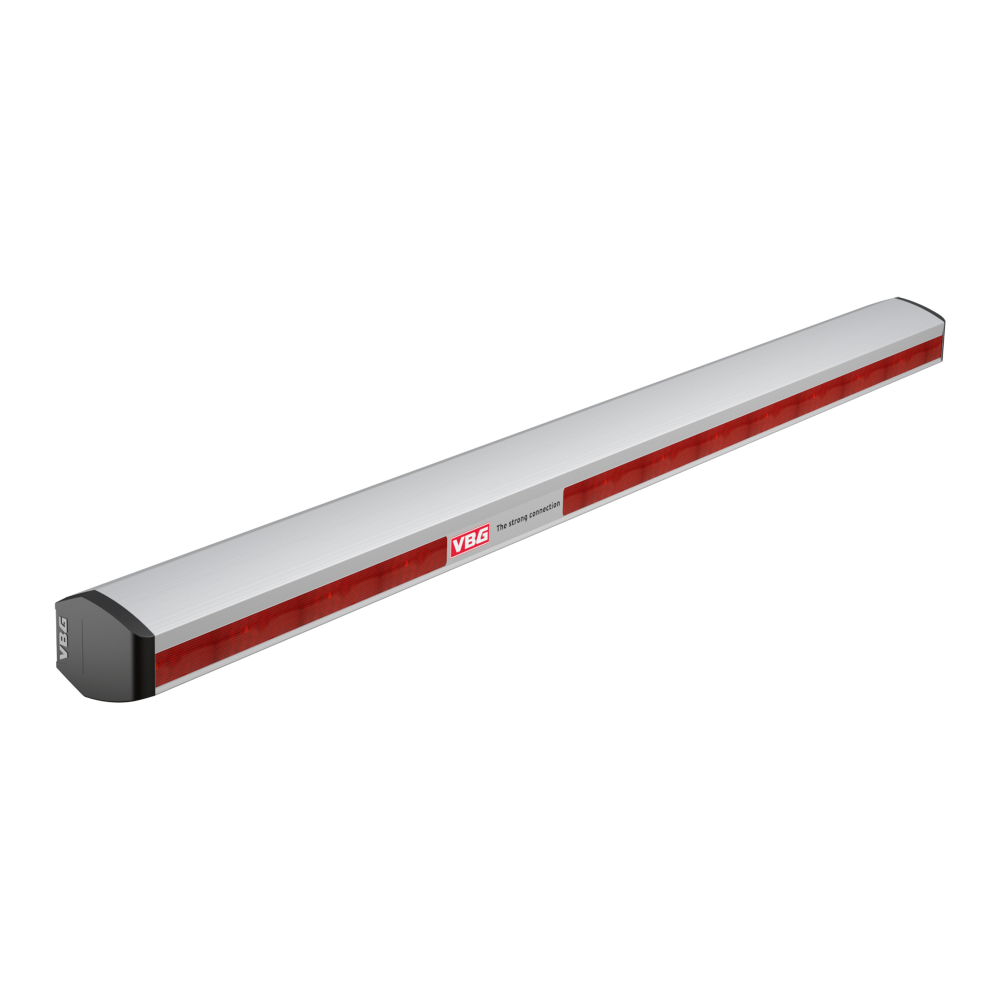

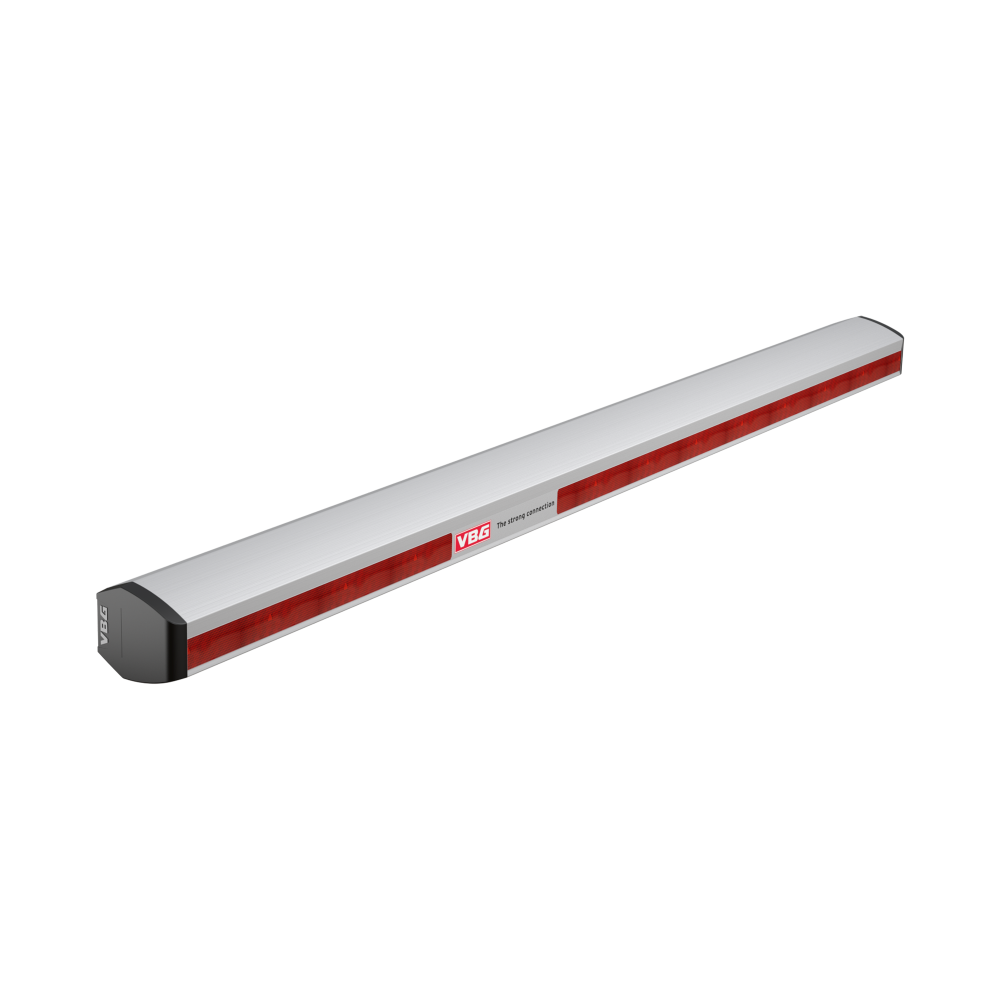

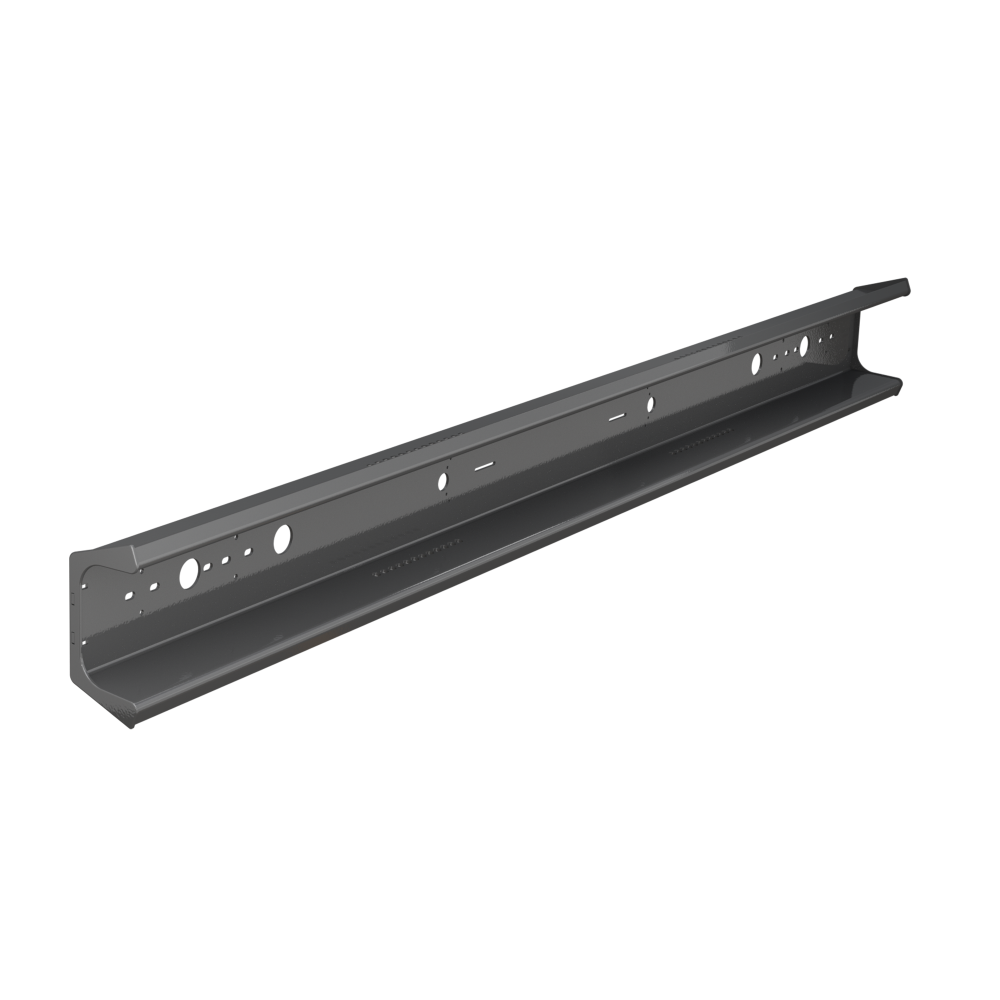

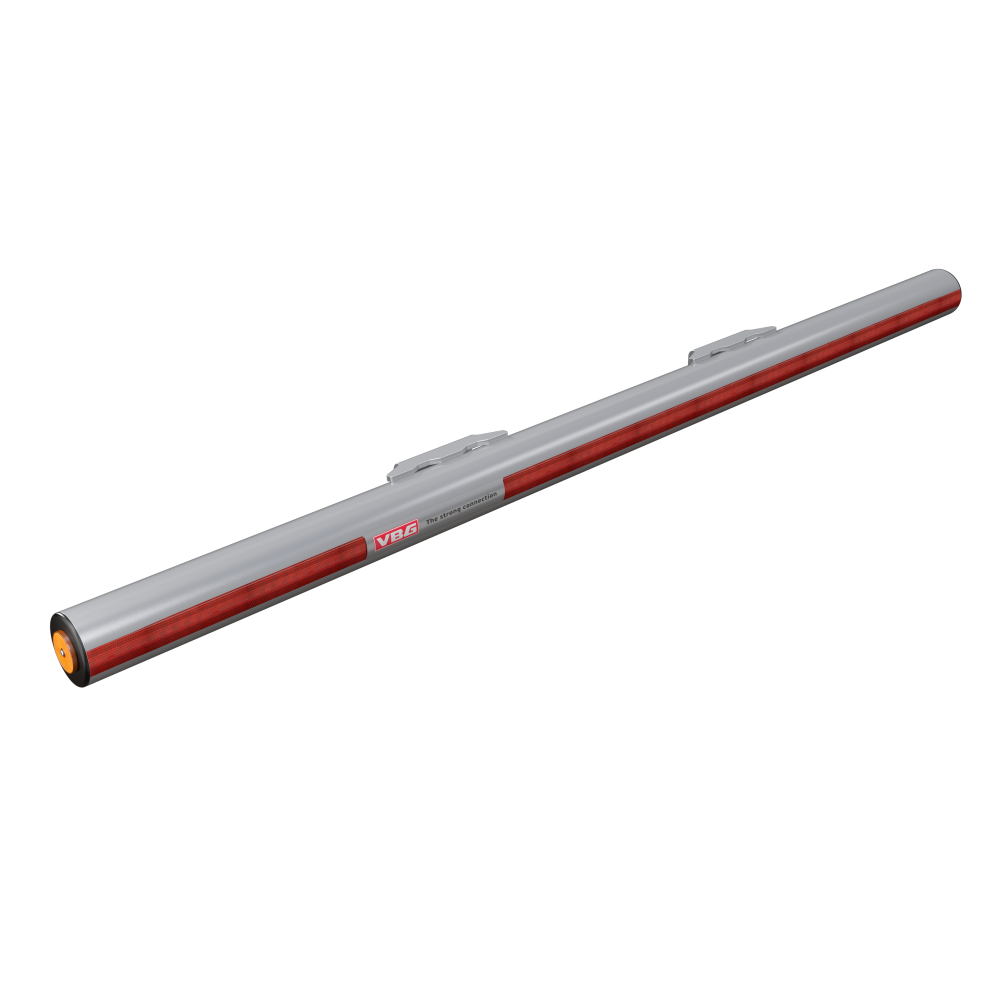

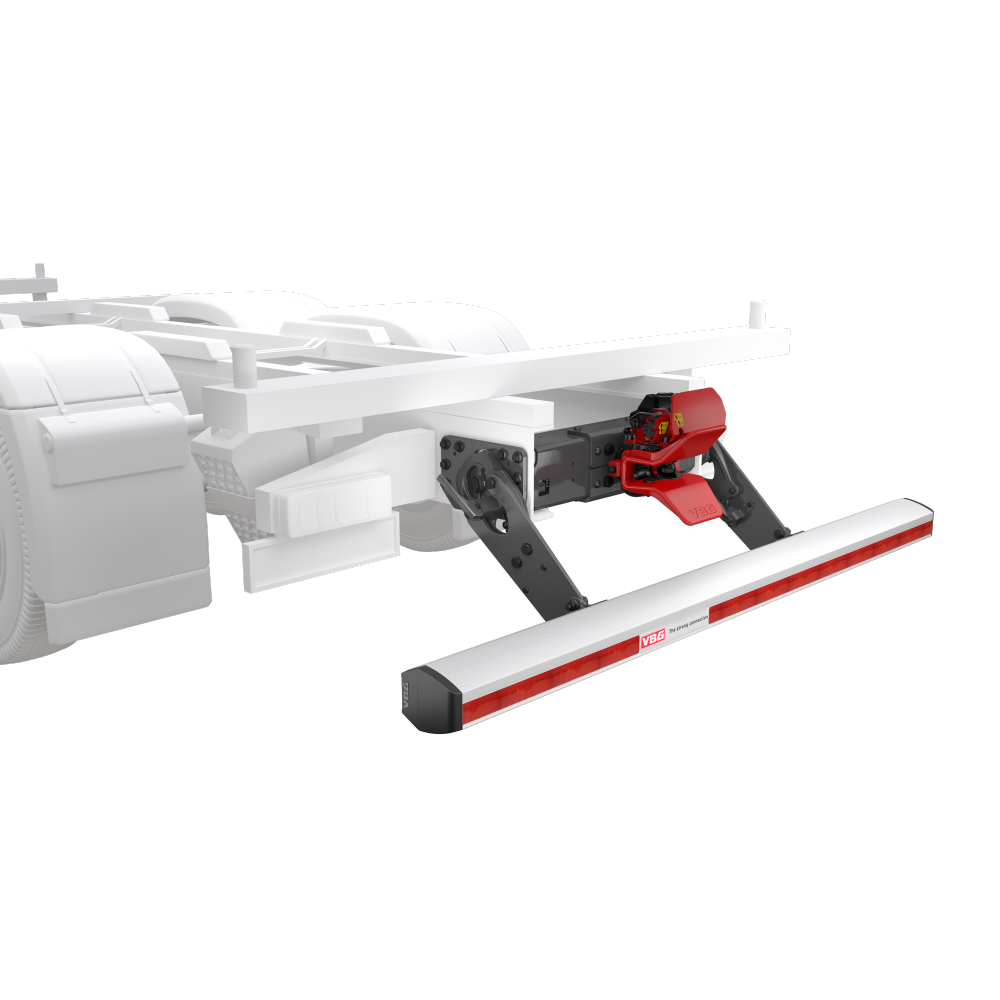

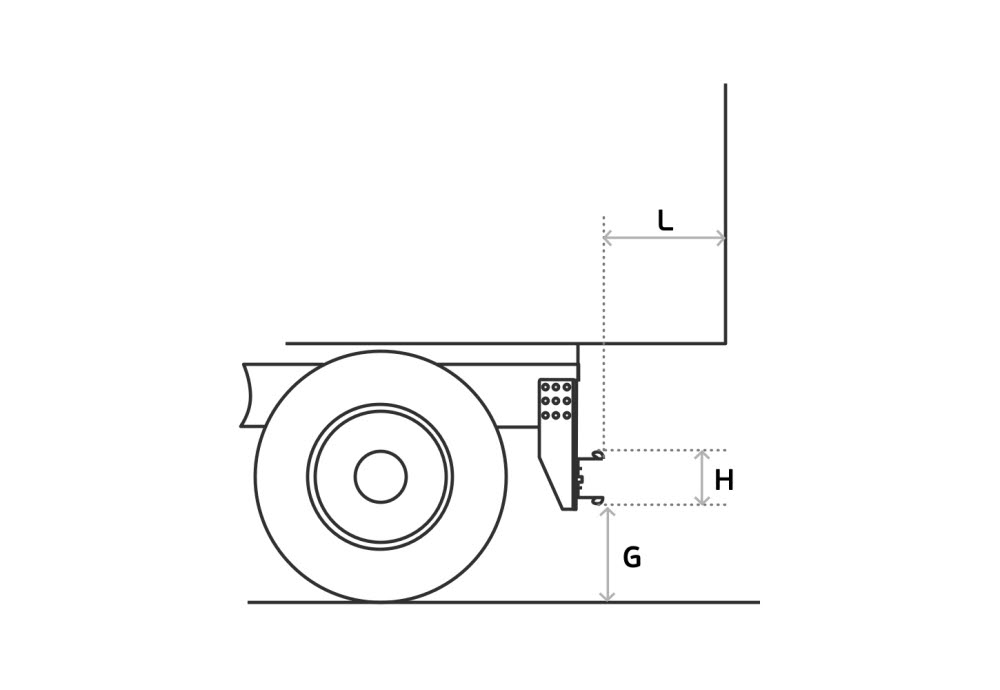

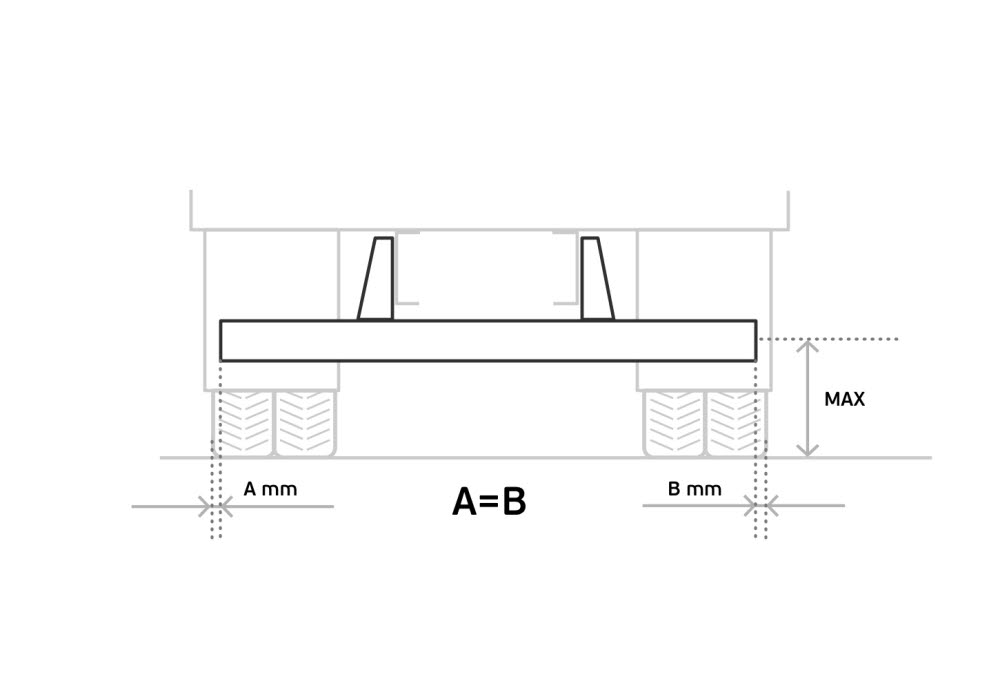

Underrun protection

In the event of a rear-end collision, the underrun protection system prevents smaller vehicles from becoming lodged underneath the truck or trailer. For the purpose of increased safety, it is an important and integrated part of VBG’s coupling solutions. VBG’s underrun protection systems are complete, flexible systems designed for variety of vehicle types, frame widths, and installation needs. All components comply with international regulations.